HDV 8000 Vacuum Concept™

Continuous Dense Phase Vacuum System

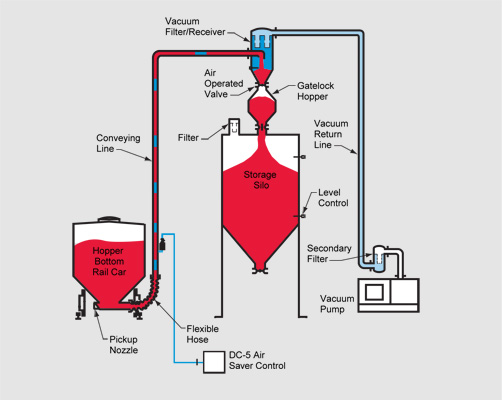

The HDV 8000 Vacuum Concept Conveying System is a dense phase, low to medium velocity, high pressure, continuous vacuum conveying system. It is generally used to convey low to high density, friable, and abrasive materials and/or other materials where degradation or abrasion is a concern. Examples include plastic pellets, breakfast cereal, granulated sugar, salt, coffee beans, pinto beans, finished detergent, pelletized carbon black and silica sand.

Typical conveying velocities are 50 to 800 feet per minute (0.25 m to 4 m/sec) and vacuum conveying pressures of up to 29 inches (737 mm) of Mercury (hg).

The material is fed into the conveying line on a continuous basis by vacuum. DC-5 Air Saver technology is used to minimize and optimize the pressure supply air which is supplied by a high pressure vacuum pump. The system includes a vacuum pickup nozzle, a vacuum conveying line, DC-5 Air Saver controls, a vacuum filter receiver, a secondary filter and a vacuum pump. For continuous conveying applications, a gatelock hopper with an inlet and outlet valve is installed at the discharge of the vacuum receiver.

Let’s Find the Right Solution for You

Contact usPartner with Dynamic Air, the industry leader in providing reliable, innovative solutions. Our team of experts is ready to understand your unique requirements and design customized solutions tailored to your specific needs, whether it’s pneumatic conveying, equipment manufacturing, or other material handling challenges. Experience the Dynamic Air difference and unlock the potential of seamless material flow, enhanced efficiency, and optimized productivity. Contact us today to discuss your project.