What is pneumatic conveying?

It’s a highly efficient method of material conveying that involves transporting dry bulk materials from one location to another, utilizing the force of air pressure. Dynamic Air specializes in the design and manufacturing of various types of pneumatic conveying systems, tailoring each solution to meet the unique needs of our clients. Find out how to choose the right system for you.

Powering Pneumatic Precision: Advanced Conveying Solutions for Every Need

Dynamic Air offers both dense phase and dilute phase pressure and vacuum conveying systems. Pneumatic conveying provides numerous advantages over traditional material handling methods.

Not only does it offer a more efficient and cost-effective way of transporting materials, but it also provides improved safety, as it reduces the risks associated with handling bulk materials manually. With fewer moving parts, pneumatic conveying systems require less maintenance and reduce the likelihood of equipment failures, making them a reliable solution for various industries.

Dynamic Air is a leading pneumatic conveying system manufacturer and has sold over 15,000 pneumatic conveying systems worldwide. We have over 50 years of experience in designing and building different types of pneumatic conveying systems for a wide variety of applications.

Whether you need to move powders, granules, pellets, or other bulk materials, Dynamic Air can design and manufacture a pneumatic material conveying system that meets your needs, improves operational efficiency, and enhances the safety of your processes.

Popular FAQs about Pneumatic Conveying Systems

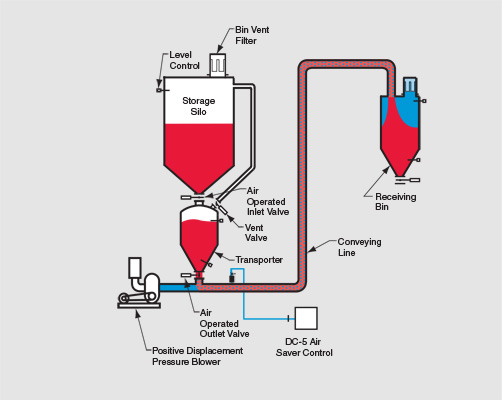

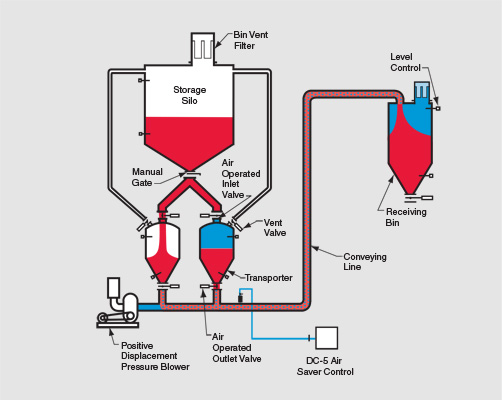

Dense phase pneumatic conveying systems transport materials at low velocity, high density, and high pressures. This method is ideal for abrasive, fragile, and moisture-sensitive materials, as it minimizes degradation and wear.

Types of Pneumatic Conveying Systems

Dynamic Air offers a range of pneumatic conveying systems to suit different needs:

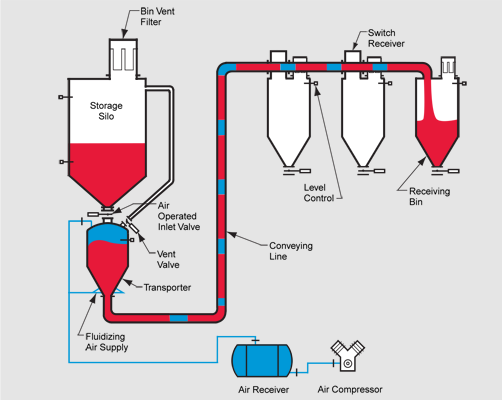

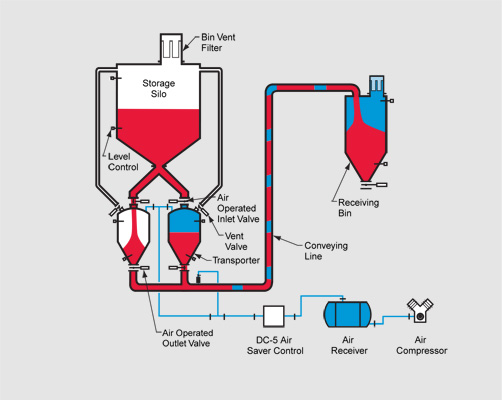

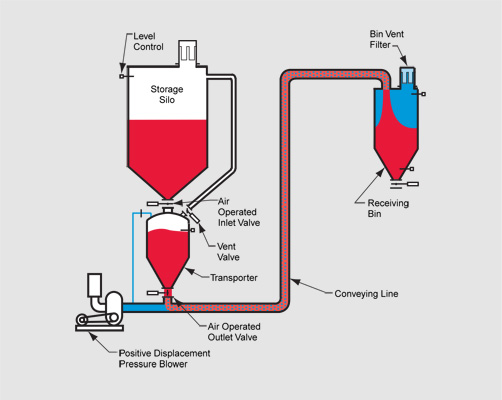

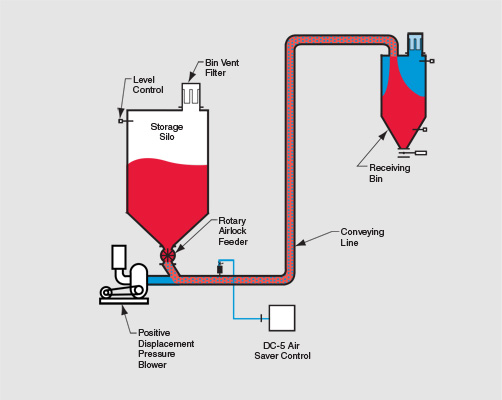

- Dense Phase Pneumatic Conveying Systems: Ideal for transporting abrasive, fragile, moisture-sensitive, or heat-sensitive materials. These systems convey the material at low velocity and use high pressure (up to 100 PSIG), minimizing material degradation and wear on the system.

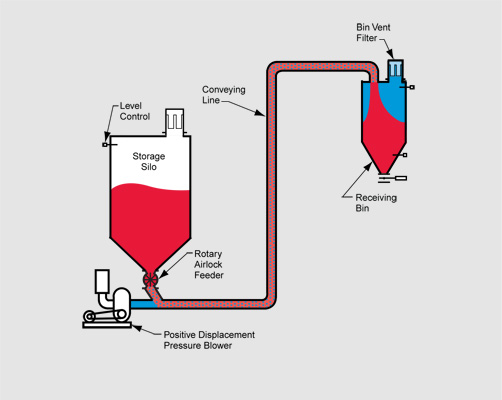

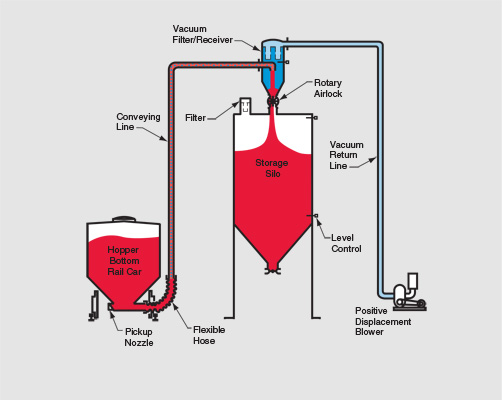

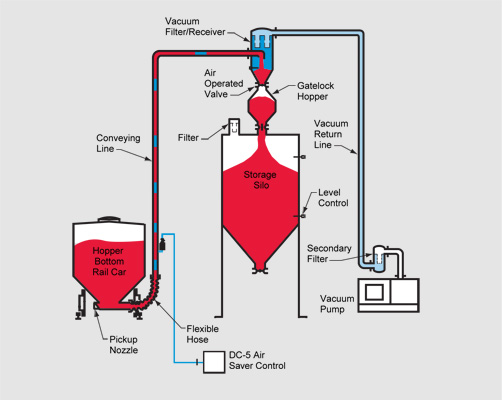

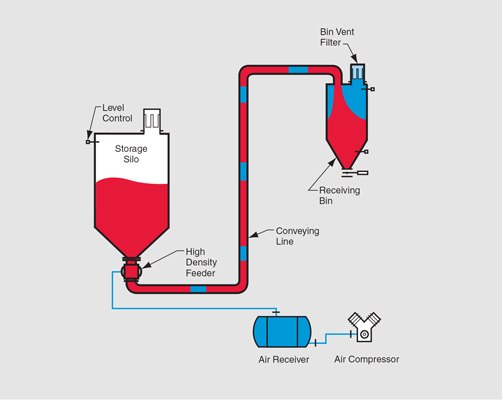

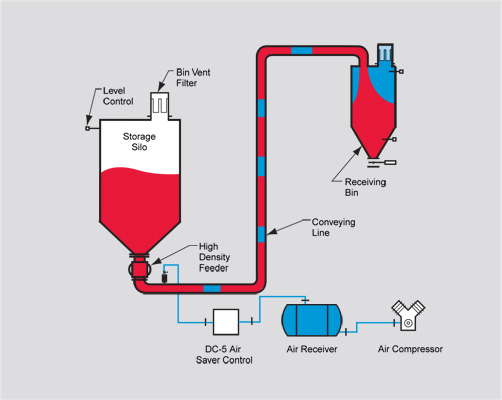

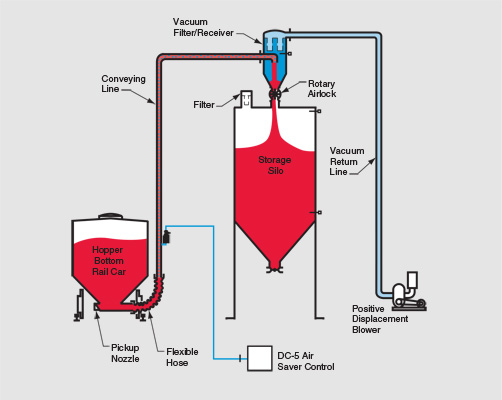

- Dilute Phase Pneumatic Conveying Systems: Suitable for non-abrasive materials that are not prone to degradation. These systems convey at relatively higher velocity and use low pressure (less than 1 atmosphere), making them more cost-effective for short distances and low capacities.

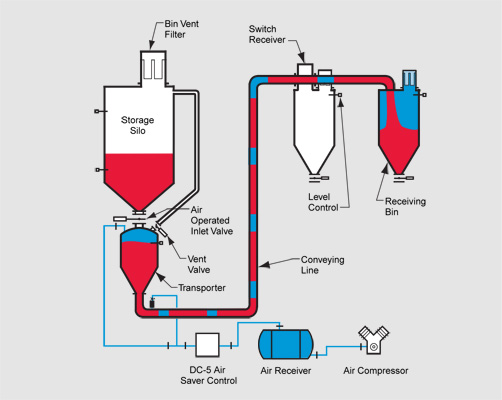

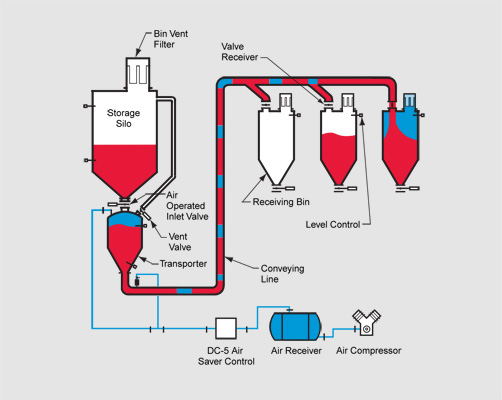

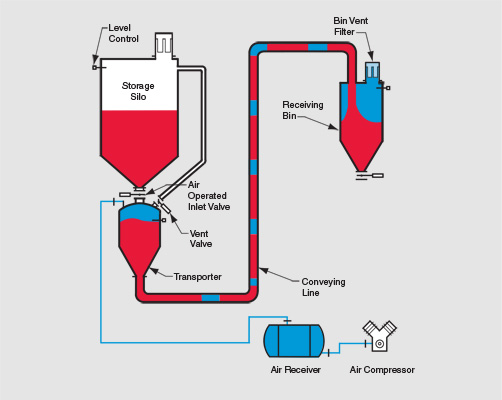

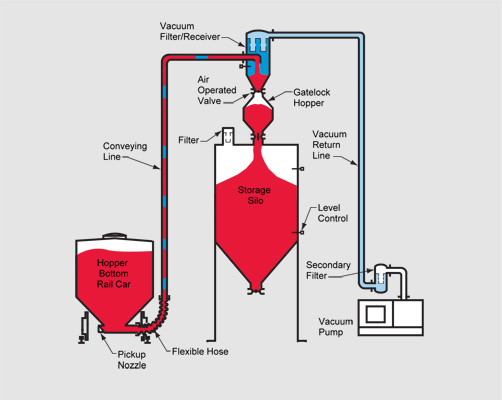

Components of Pneumatic Conveying Systems

A pneumatic conveying system comprises essential components such as:

- Feed systems (transporters, rotary airlocks, Accu-Flo screw feeders, and vibratory feeders)

- Pipelines (conveying lines and bends)

- Air movers (blowers and compressors)

- Air filtration units (Modu-Kleen dust filters and dust collectors)

- Material receivers (silos, hoppers, and bins)

- Control systems (PLCs and sensors)

- Discharge systems (such as Vibra jet bin discharge systems, GYRO EX vibratory bin dischargers, Dyna-Slide gravity conveyors, inflatable seat valves, and rotary valves).

These components work together to ensure efficient, safe, and reliable bulk solid conveying and handling.

Benefits of Pneumatic Conveying Systems

Pneumatic conveying systems offer several advantages over traditional material handling methods, such as mechanical conveyors and manual handling:

- Efficiency: Automated and continuous transport of materials over long distances.

- Flexibility: Can handle a wide range of materials, including powders, granules, and pellets.

- Safety: Reduces manual handling of materials, lowering the risk of accidents compared to manual handling or mechanical systems.

- Low Maintenance: Fewer moving parts result in less wear and tear, reducing maintenance costs compared to mechanical conveyors.

- Dust Control: Enclosed systems prevent dust from escaping, maintaining a cleaner and safer work environment.

Dynamic Air's Expertise in Custom Pneumatic Conveying

Dynamic Air provides comprehensive solutions for dry bulk material handling services. Our expertise in designing and manufacturing pneumatic conveying systems ensures that we deliver high-quality, customized solutions to meet the specific needs of our clients. Whether you need material handling and conveying systems, bulk material handling equipment, or Dynamic Air support services, we have the experience and technology to optimize your operations.

For reliable, custom pneumatic conveying solutions, contact Dynamic Air today and experience the difference our tailored systems can make in your processes.