Why Use Boosters in Dense Phase Pneumatic Conveying?

Understanding Dense Phase Pneumatic Conveying

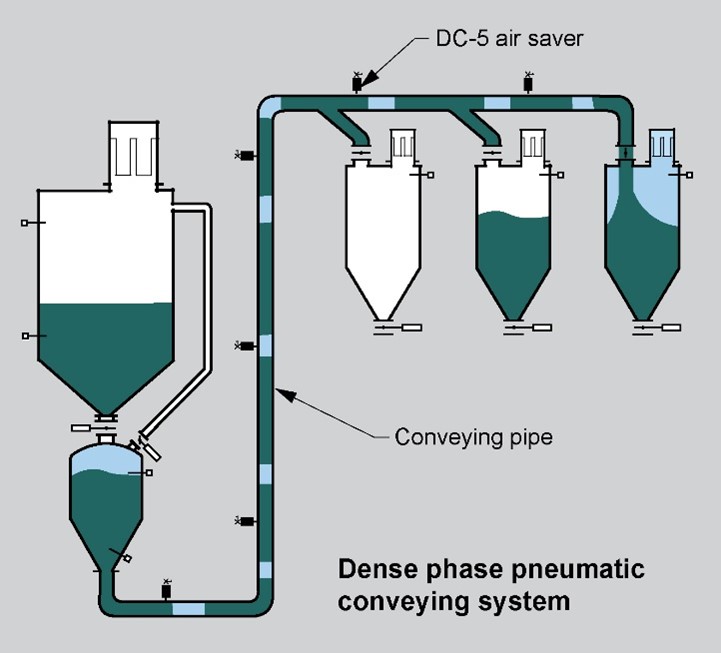

Dense phase pneumatic conveying is a highly efficient method to pneumatically convey materials, and is particularly suitable for handling abrasive, fragile, or difficult-to-convey materials, and/or for long-distance or high-rate conveying applications. A dense phase system utilizes compressed air at 100 to 125 psig (7 to 8 BarG) pressure air to move materials in dense “slugs” at relatively low velocities, reducing wear and tear on equipment, minimizing material particle degradation, and improving energy efficiency. Dense phase systems are described as high-pressure/low-velocity systems that have a low air-to-material ratio, making them highly energy efficient.

Dense Phase Pneumatic Conveying Without Boosters has Limitations

While dense phase conveying systems are ideal for conveying materials long distances and at high rates, there are still some limitations when boosters are not employed. Compressed air is required to move materials through the convey pipe. If the convey distance is too long for the air pressure to overcome it could lead to potential blockages, making it difficult to maintain consistent material flow and impacting the overall efficiency and reliability of the conveying process. This is where boosters come into play. Boosters in dense phase conveying help overcome these limitations by maintaining the optimal flow of materials over extended distances and through complex system layouts. Boosters are also known as air savers, air inlet devices, air fluidizers, or air assist devices.

How Boosters Work in Dense Phase Conveying

Boosters, or air savers, in dense phase conveying systems work by injecting short bursts of compressed air into the conveying line to maintain material flow by preventing short “slugs” of conveyed material to combine into fewer longer “slugs”. When many short “slugs” of conveyed material combine into fewer longer “slugs”, the pressure required to keep the material in motion increases. If there is insufficient supply pressure to keep the material in motion, system plugging (a stoppage) occurs. So, in short, periodically adding air along the convey pipe via boosters ensures that conveyed material remains in motion, preventing blockages and maintaining the efficiency of the system. Additionally, boosters allow the conveying system to deliver the full convey pressure to any point (even the end) along the conveying pipe.

Benefits of Using Boosters in Dense Phase Conveying

Velocity Control and Improved Efficiency: Because boosters inject air along the conveying pipe they can provide very accurate control of the conveying velocity. Slower conveying velocity reduces energy consumption, reduces pipe wear, minimizes material particle degradation, and eliminates plugging – all of which results in lower operational costs. In many cases, stopping production for just a few hours or days can far exceed the cost of the entire conveying system.

Overcoming Pressure Limitations: By adding air at strategic points, boosters extend the practical conveying distance of a dense phase system, overcoming the natural pressure limitations of the system, which is particularly beneficial in high-pressure applications where the pressure differential must be managed effectively. Think of boosters as the “lubricant” that makes the convey system operate better.

Enhanced System Flexibility: Boosters allow for greater adaptability in system design, making it easier to accommodate longer or more complex layouts without sacrificing performance.

Choosing the Best Conveying System Design

When selecting a dense phase conveying system, several factors need to be considered:

- System Capacity and Conveying Distance: The size and length of your system will determine the type and number of boosters required.

- Material Properties: The abrasiveness, particle size, and other characteristics of the material being conveyed will influence booster selection.

- Budget and Space Constraints: Cost and available space for installing boosters will also play a role in the decision-making process. However, keep in mind that the operating cost savings of an efficient conveying system is usually far greater than the cost to add energy-saving features.

Partner with Dynamic Air for Efficient Pneumatic Conveying

Using boosters in dense-phase pneumatic conveying systems can significantly improve efficiency, overcome pressure limitations, and enhance system flexibility. By maintaining optimal material flow and adapting to complex layouts, boosters ensure a more reliable and cost-effective conveying process. If you’re facing challenges with your dense phase conveying system or looking to optimize its performance, contact Dynamic Air for a consultation. Our experts can design a system for your specific needs and ensure it operates at peak efficiency.

Let’s Find the Right Solution for You

Contact usPartner with Dynamic Air, the industry leader in providing reliable, innovative solutions. Our team of experts is ready to understand your unique requirements and design customized solutions tailored to your specific needs, whether it’s pneumatic conveying, equipment manufacturing, or other material handling challenges. Experience the Dynamic Air difference and unlock the potential of seamless material flow, enhanced efficiency, and optimized productivity. Contact us today to discuss your project.