Choosing the Right Pneumatic Conveying System for Your Needs

The world of pneumatic conveying can seem complex at first glance, with all the talk of dense phase, dilute phase, and medium phase systems. This guide will help you navigate the different options and choose the perfect pneumatic conveyor system for your specific bulk material handling needs.

Let’s start with the basics.

What is Pneumatic Conveying?

It’s a method of transporting dry bulk materials like powders, granules, and pellets through enclosed pipelines using pressurized air (or other gasses such as N2) or vacuum. This dry bulk transportation method is widely used in various industrial processes, including food processing, pharmaceuticals, chemicals, and plastics. It offers a clean and efficient way to move materials around your facility.

Now, onto the fun part–choosing your type of system.

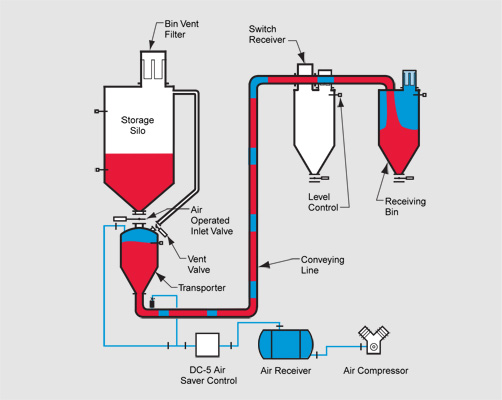

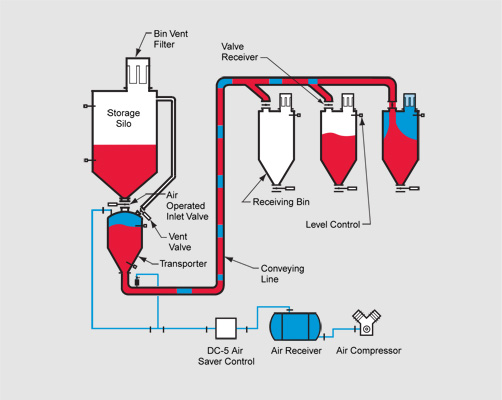

What are Dense Phase Pneumatic Conveying Systems?

Dense phase pneumatic conveying is a method that uses a pressurized gas stream to push a dense plug of material through a pipeline.

- Dense Phase is Ideal for:

- Abrasive materials: Think sand, gravel, glass batch, refractory batch. Dense phase minimizes the amount of particles that come in contact with the conveying pipe wall, minimizing conveying pipe wear.

- Fragile materials: For example, coffee beans, granulated sugar, dry laundry detergent, even breakfast cereal! Due to low conveying velocities and also because the material moves in a dense slug, only a small percent of the particles actually contact the conveying pipe wall and are subject to degradation from the conveying pipe. Dense phase ensures your delicate materials stay intact.

- Moisture-sensitive and oxidizable materials: Because the process environment is controlled by the dry compressed air or N2 source, Dense phase keeps your materials dry and prevents unwanted reactions with moisture or oxygen.

- Explosive or flammable materials: Here, safety is paramount. Dense phase can use inert gas to minimize explosion risks by preventing an explosion in the first place!

- Quiet operation: Dense phase systems tend to be gentler on the ears, creating a more peaceful work environment.

- Heat-sensitive materials: Dense phase can use cool conveying gas to keep your materials happy, ensuring quality control in temperature-sensitive material handling.

- High capacity and long distances: Dense phase excels at bulk-density material movement over impressive distances, making it ideal for large-scale operations.

- Multiple destinations: Need to send your materials to different locations within your facility? Dense phase can handle complex conveying systems with multiple discharge points.

- Existing compressed air: Already have a compressed air system in place for other operations? Dense phase might be a good fit, leveraging your existing resources.

- Dust control: Due to the lower amount of compressed gas use, Dense phase systems are champions of dust containment, promoting a clean and healthy work environment.

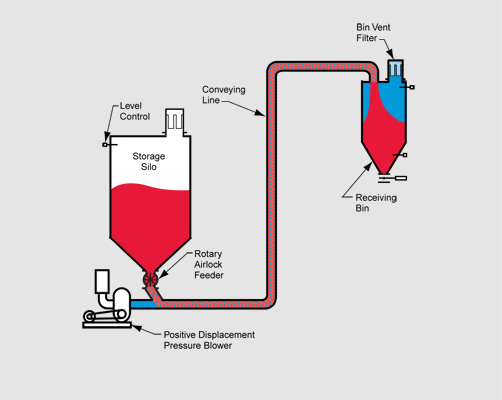

What are Dilute Phase Pneumatic Conveying Systems?

Dilute phase pneumatic conveying utilizes a high-velocity air stream to suspend and transport dry, bulk materials through a pipeline.

- Dilute Phase is Ideal for:

- Non-abrasive materials: Plastics, grains, or flour. A dilute phase conveying system is perfect for these non- abrasive materials.

- Cost-effectiveness: Is budget a major concern? Dilute phase systems generally have a lower initial cost, making them a good choice for budget-friendly applications.

- Short distances and low capacities: Perfect for smaller-scale operations or applications with shorter conveying distances.

- Noise doesn’t matter: If noise isn’t a major concern in your work environment, dilute phase can be a good option.

- High conveying air temperatures: If hot air is not a concern, dilute phase would be suitable for materials that can handle higher temperatures.

- Limited starting height: Dilute phase requires less headroom at the beginning of the system, making it adaptable to facilities with space constraints.

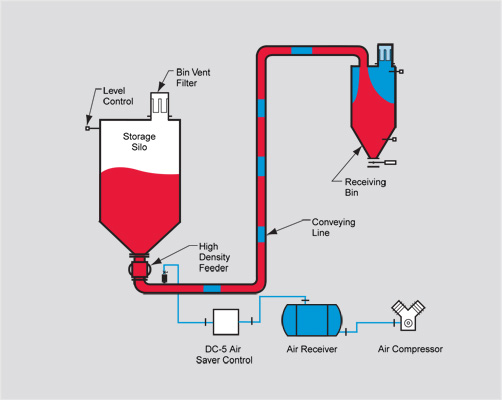

What are Medium Phase Pneumatic Conveying Systems?

Medium phase pneumatic conveying sits between dense phase and dilute phase in terms of both material concentration and air velocity.

- Medium Phase is Ideal for:

- Dense phase is ideal, but headroom is limited due to space constraints.

- Material degradation is a slight concern, but not a dealbreaker.

- Similar benefits to dilute phase in terms of cost for cost-effective operations.

Still Don’t Know What System Type is Right for You?

Dynamic Air’s application engineers are experts at testing your material and matching the right system requirements to your needs and coming up with custom solutions. They’ll consider factors like:

- Material properties: Abrasive, fragile, density, etc.

- Conveying distance: How far does your material need to travel?

- Capacity: How much material do you need to move per hour?

- System complexity: Single or multiple pick-up/discharge points?

- Pressure vs. vacuum: Dense vs. dilute phase?

- Cost-effectiveness: Finding the balance between budget and needs.

Dynamic Air Can Help You Find the Right Conveying System

Contact Dynamic Air today for a free consultation and let our experts guide you to the perfect custom pneumatic conveying system for your specific industrial operation. We can help you achieve efficient bulk material handling and optimize your processes.

Let’s Find the Right Solution for You

Contact usPartner with Dynamic Air, the industry leader in providing reliable, innovative solutions. Our team of experts is ready to understand your unique requirements and design customized solutions tailored to your specific needs, whether it’s pneumatic conveying, equipment manufacturing, or other material handling challenges. Experience the Dynamic Air difference and unlock the potential of seamless material flow, enhanced efficiency, and optimized productivity. Contact us today to discuss your project.