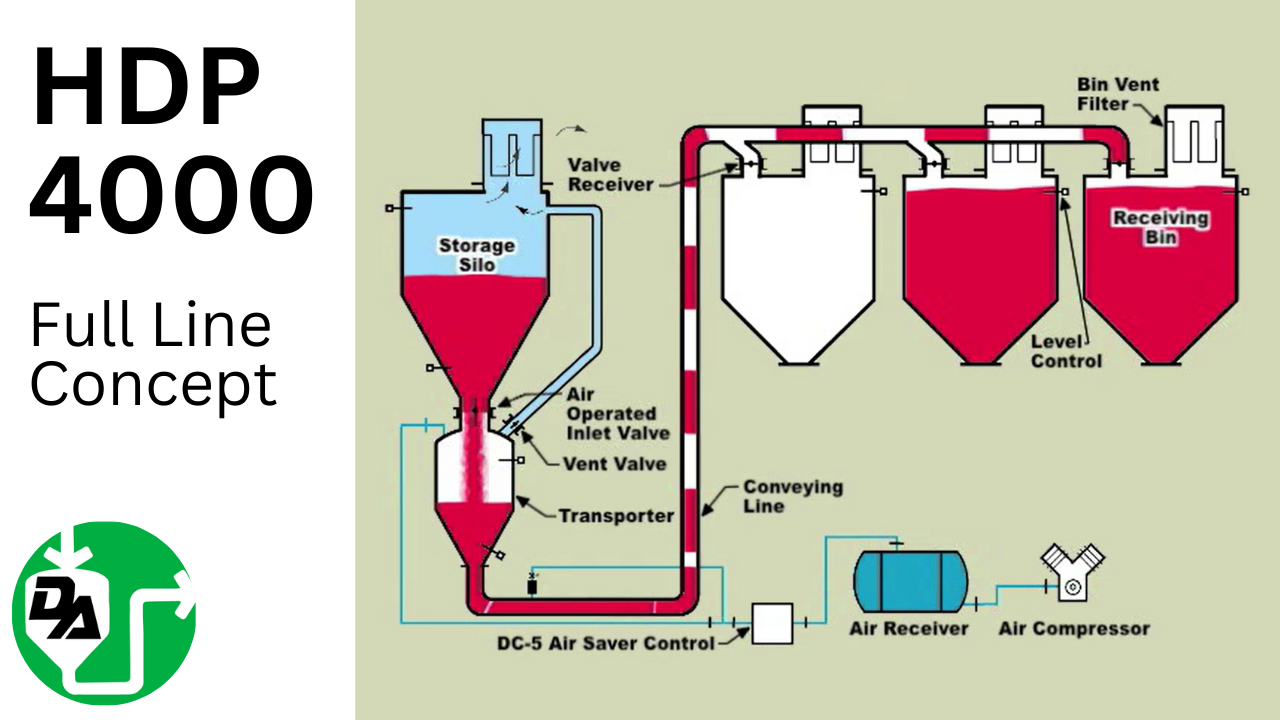

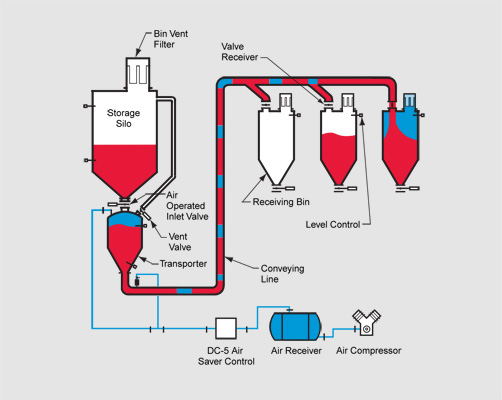

HDP 4000 Full Line Concept™

Dense Phase Pressure System

The HDP 4000 Full Line Concept Pressure Conveying System is a dense phase, medium to high pressure, low to medium velocity, batch type conveying system. It is generally used for conveying medium to high density, heat sensitive, semi-abrasive and/or very abrasive, cohesive, and/or very fragile materials in almost any particle size range over long distances. Examples include silica sand, glass batch, granulated sugar, powdered sugar, finished breakfast cereal, coffee beans, plastic pellets, bentonite, cement, starch, silica flour, ball clay, kaolin clay, zinc oxide and alumina.

Typical conveying velocities are generally in the range of 100 to 1000 feet per minute (0.5 m to 5 m/sec) and the conveying pressure up to 100 PSIG (7 barg).

This concept uses a single, non-fluidizing type pressure vessel to feed material into the conveying line at maximum density. DC-5 Air Saver technology is used to minimize and optimize the high pressure air which is supplied by a high pressure – up to 100 PSIG (7 barg) – air compressor. This concept does not need diverter valves but uses valve receivers which provide a distinct maintenance advantage as they are located on the silo tops for easy access.

Let’s Find the Right Solution for You

Contact usPartner with Dynamic Air, the industry leader in providing reliable, innovative solutions. Our team of experts is ready to understand your unique requirements and design customized solutions tailored to your specific needs, whether it’s pneumatic conveying, equipment manufacturing, or other material handling challenges. Experience the Dynamic Air difference and unlock the potential of seamless material flow, enhanced efficiency, and optimized productivity. Contact us today to discuss your project.