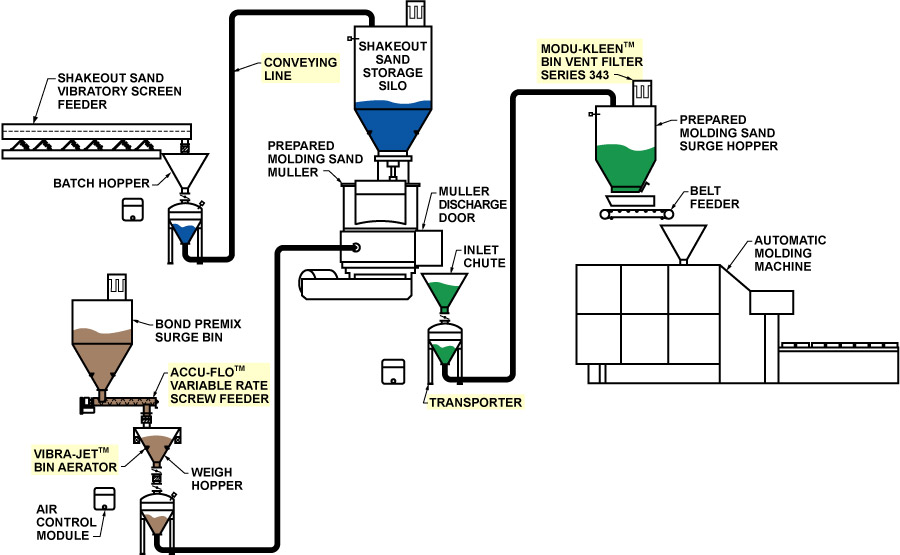

Shakeout Sand, Bond Premix and Prepared Molding Sand Delivery Systems

Features

- Low cost installation

- Simple and flexible installation... can route conveying lines almost anywhere

- Dust tight process

- Very low maintenance due to very few moving parts

- Automated process

- Complete guaranteed project responsibility

- Dust is utilized 100% in the process

- Quiet operation

- Very low equipment wear due to abrasion

- Very high precision batching

- 33% bond savings due to elimination of bond loss up through muller dust collector

- Fast ROI payback due to better quality control of mixed sand

- Reduced labor costs

- Easily expandable to deliver to future mullers

- Can be designed to accommodate any rate

- Lower bond cost using bulk railcars or trucks versus bags

- Reduction of workman's compensation claims by eliminating manually handling bags of bond

- Easily expandable to deliver to future destinations

Let’s Find the Right Solution for You

Contact usPartner with Dynamic Air, the industry leader in providing reliable, innovative solutions. Our team of experts is ready to understand your unique requirements and design customized solutions tailored to your specific needs, whether it’s pneumatic conveying, equipment manufacturing, or other material handling challenges. Experience the Dynamic Air difference and unlock the potential of seamless material flow, enhanced efficiency, and optimized productivity. Contact us today to discuss your project.