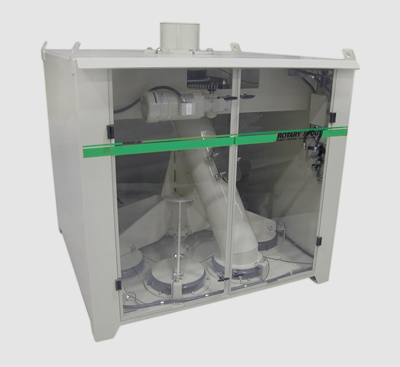

Rotary Spout

Divert dusty, granular or abrasive material up to fifteen positions without cross-contamination or dusting

The Rotary Spout automatically diverts granular materials from a single source, such as a pneumatic conveying system or a gravity feed chute, to as many as fifteen different bins, hoppers, or silos as required. The indexing spout slopes at a 60° angle to improve material flow and minimize material buildup at corners and seams. Welds are smooth so there are no dead spots for material to collect, making the Rotary Spout ideal for food products or other applications where cross-contamination is a major concern.

Inflatable air seals eliminate dust problems

The heart of the Rotary Spout is its inflatable seal, which contains pressure to 35 PSIG as standard and up to 100 PSIG for special applications. These seals are located at the upper pivot point and at each of the outlet port connections.

When the main spout indexes to the desired port, both the top and bottom seals inflate, squeezing the spout from both directions to form a dust-tight pressure seal. The blind or unused ports are similarly sealed when the spout is not moving so hoppers and bins are not exposed to the atmosphere.

To index the spout to a new position, the seals are deflated, giving the indexing spout clearance to rotate freely 360° around the center support shaft with minimal friction and effort. The indexing spout is supported by a heavy-duty center shaft and bearing assembly.

Features:

- Dust-tight design

- Positive indexing

- Positive inflatable air seals

- 60° spout angle

- Select up to fifteen positions

- Fully enclosed

Download PDF

Let’s Find the Right Solution for You

Contact usPartner with Dynamic Air, the industry leader in providing reliable, innovative solutions. Our team of experts is ready to understand your unique requirements and design customized solutions tailored to your specific needs, whether it’s pneumatic conveying, equipment manufacturing, or other material handling challenges. Experience the Dynamic Air difference and unlock the potential of seamless material flow, enhanced efficiency, and optimized productivity. Contact us today to discuss your project.